No one that is involved in design wants to deal with Worm gears. Just the engineers or designers that are familiar with this type of applications have no problems to understand the development, working conditions, manufacturing and design of a worm gear set.

In my case, it took me a long period of time to have an idea about the minor details of this mechanical element, and I am just able now to define them geometrically, calculate the forces and evaluate the proper assembly and understand some cases of failures.

I have read some articles and gear handbooks to verify the informatoin given in this application for Android, wich is going to be available in three of four weeks.

Here you have some links to useful information:

KHK gears

Autodesk Basic Information

Research gate Worm Gears PDF

I will add more information of worm gears while I am progressing with the application.

Worm Input motion:

Here we have the worm wheel in motion with the worm. Input and output together.

Now the final animation is ready. Time to work in the app.

It took me more time than I wanted, but the app is now available in Google Play.

The application will help you to design a worm gear according to the reccomendations found in different articles and books.

You may need to know the transmission ratio of your gearset, as well as the center distance between worm and wormgear.

After filling those two variables, the worm should be defined with a set of parameters that are neccesary to calculate the whole gearset. The app will give you some indications to fill them.

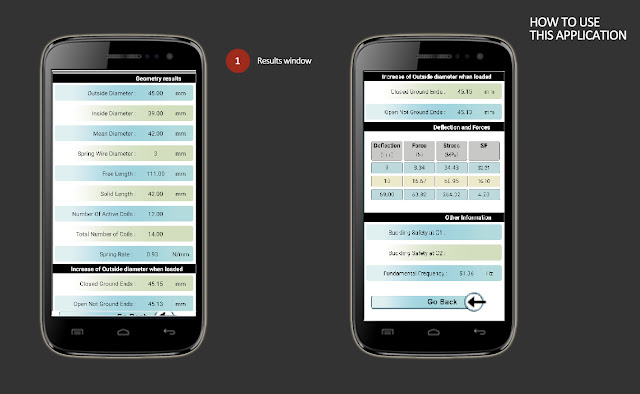

The following images explain the way to work with this new application:

The application is available in Google Play:

What have I learned during the application development and the usage of this type of mechanical ellements...

First of all, this type of gear set has the difficulties of a typical gear set design with the difficulties of the a bevel gear transmission.

The capacity of provide a huge reduction in a very small space would drive engineers to think in this transmission as a solution instead of using, maybe a planetary system. But, consider the following facts:

- Worm gear manufacturing is difficult and should be done by specific manufacturing suppliers that could provide the quality you require for your application.

- Worm wheel, may not be as difficult to machine as the worm and it will not need a quality grade as tight as the worm also, because it will tend to wear and accomodate the worm geometry to the tooth surface and part of the geometric deviations will dissapear, but it will need some work to think the way you want to attach this worm wheel (in general a piece that would be serviceable) to the ouput shaft.

- The location of the gear contact has, in worm gear design, three possible linear deviations. Compared to a typical spur gear set, the worm and worm wheel could move in X, Y and Z direction, Probably the center distance is the one that in general can not be adjusted by shims, but the axial location of the worm as well as the axial direction of the worm wheel can be adjusted slightly.

Doing that, you can reduce the transmission error and adjust the backlash of your system.

- Lubrication, Lubrication and Lubrication. It is essential to provide good lubrication to the gear mesh because the relative motion between gears is almost sliding. Therefore, oil type and oil lubrication method should be designed carefully.

Here you have some links to useful information I found about worm, and worm wheels: